Glossario

ANNEALING:

Thermic treatment that can be done. The tubes are brought to a high temperature (1050°C) in ovens and the original inter crystalline structure is restored.

DIAMETER:

Normally, when “diameter” is indicated, it refers to outside diameter of the tube.

EDDY CURRENT:

Is based on the variation on an electrical current applied to the tubes to tested. Special coils sends and receives signals to an oscilloscope that, in the case of a non continuity, activates an acoustic signal and the defect tube is scrapped.

Thermic treatment that can be done. The tubes are brought to a high temperature (1050°C) in ovens and the original inter crystalline structure is restored.

DIAMETER:

Normally, when “diameter” is indicated, it refers to outside diameter of the tube.

EDDY CURRENT:

Is based on the variation on an electrical current applied to the tubes to tested. Special coils sends and receives signals to an oscilloscope that, in the case of a non continuity, activates an acoustic signal and the defect tube is scrapped.

GRINDING:

Processing that improves the aesthetic aspect without having the mirror characteristic. The surface remains dull.

GRIT:

The measurement that indicates the degree of grinding. The higher the figure, the finer the grinding.

INERT GAS:

Gas mixture with high purity based on argon that is used to eliminate the presence of oxygen in the welding zone.

POLISHING:

Mirror polishing applied on the external surface of the tube. Increases reflection properties (mirror) and gives a better aesthetic appearance.

RA:

The measurement that indicates the degree of mirror polishing.- SCOTCH BRITE:

A grinding material used for outside grinding. The characteristic of this process is that the aspect does not change with the consumption of the grinding material which results in a uniform aesthetic aspect. - STRAIGHTNESS:

Means the straightness of the tube. It is specified in mm that indicates the deviation from as straight line between the two ends and the middle of a one metre long tube. -

-

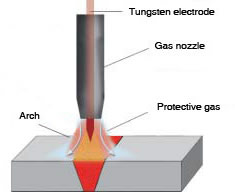

T.I.G. (Tungsten Inert Gas):

Welding method that takes place in a neutral environment and uses an electrical arch that goes from an electrode to the surface of the tube that is being welded. The integrity of the electrode is guaranteed by the inert gas.

This type of welding can be done with or without adding material. Welding thin materials, like those in tube production, is normally done without adding material. A protection gas (inert gas) flows though the nozzle and protects the weld bath and the tungsten electrode.

This type of welding can be done with or without adding material. Welding thin materials, like those in tube production, is normally done without adding material. A protection gas (inert gas) flows though the nozzle and protects the weld bath and the tungsten electrode.

WELD BEAD :

Aggregation of material that takes place along the weld area, both on the outside and the inside of the tube. The surplus is removed from the outside and the inside, depending on tube diameter, and the thickness of the weld bead is equal to the thickness of the material. In our production all tubes have external weld bead removed and tubes with external diameter over 30mm have the excess weld bead rolled on the inside.